What is PCB(Printed Circuit Board) Connector

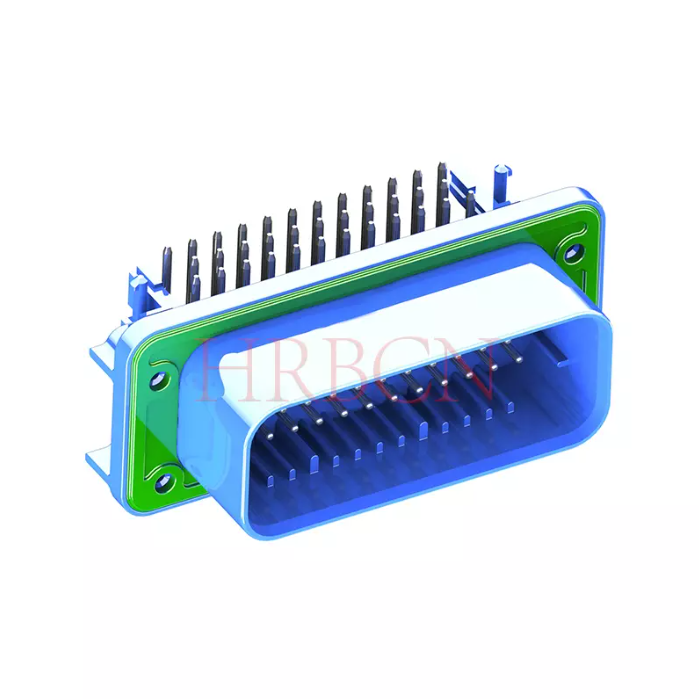

A PCB connector is an electrical interface designed to join wires, cables, modules, or other circuit boards directly to a printed circuit board. It provides a secure, removable connection point that enables signal transmission, power delivery, and modular assembly without permanent soldering. PCB connectors come in many forms-such as screw terminals, pin headers, and plug-in wire-to-board connectors-each engineered to support different current levels, mounting orientations, and application needs. They are essential in electronics, appliances, industrial controls, automotive systems, and every device requiring stable board-level connectivity. HRBCN is a certified connector manufacturer with 55,000m² facilities, automated production, and reliable PCB connector solutions trusted worldwide. Browse below to view our Connectors!

Feature Box

Stable Performance

Engineered PCB connectors deliver secure, low-loss electrical transmission across boards and modules. Their certified materials and durable contacts ensure consistent performance under vibration, heat, and frequent plug-in cycles in demanding applications.

Reliable Connection

High-precision contact structures maintain strong signal integrity, prevent intermittent faults, and support long-term equipment reliability. Ideal for industrial controls, appliances, and electronics requiring stable board-level connections.

Design Flexibility

Available in multiple types—screw terminals, pin headers, plug-in wire-to-board systems—these connectors help engineers optimize PCB layouts, simplify wiring, and improve assembly efficiency across consumer and industrial devices.

Wide Application

Versatile mounting options and robust construction make PCB connectors suitable for diverse markets including consumer electronics, industrial automation, automotive systems, and smart appliances requiring efficient electrical interconnection.

Application

PCB connectors support reliable power and signal transmission across home appliances, industrial automation systems, and high-density data-center equipment, ensuring stable board-level performance in diverse real-world environments.

Heat Pump Systems

In modern heat pump units, RAST 5.0 PCB connectors provide stable and compact board-level connections for control modules, sensors, and power interfaces. Their direct plug-in design supports fast installation and ensures reliable performance under outdoor temperature fluctuations, vibration, and long-term continuous operation.

Heating & HVAC Systems

In building heating and HVAC systems, RAST 5.0 PCB connectors ensure secure and vibration-resistant electrical connections for pumps, control units, valves, and monitoring modules. Their coding options prevent mis-mating during maintenance, while durable housing materials support long-term operation in humid and high-temperature environments.

Home Smart Appliances

In smart home devices like refrigerators, washers, and air-conditioners, PCB connectors provide compact, secure connections for control boards, supporting frequent wiring changes and ensuring lasting reliability in domestic environments.

PCB Connector Installation and Maintenance Tips

Ensure Proper Orientation and Alignment

Always align connectors with PCB pads or housings before insertion to avoid bent pins, poor contact, or long-term reliability issues.

Use Correct Tools for Secure Wiring

Apply proper crimping or tightening tools to achieve stable mechanical and electrical connections, preventing loose wires or intermittent signals.

Inspect Contacts and Housing Regularly

Check terminals, locking structures, and insulation for oxidation, deformation, or wear to maintain consistent conductivity and safe performance.

Clean and Maintain According to Environment

Remove dust, moisture, or contaminants and ensure connectors in high-vibration or high-temperature areas receive scheduled inspection and maintenance.

Resource

- Name

- Update

- Size

- Downloads

- Thumbnail

- Download

- Copy Link

- ISO TUV

- 2022-07-06

- 1.17MB

- 534

-

- Download

- Copy Link

- UL Certification

- 2022-07-06

- 636KB

- 511

-

- Download

- Copy Link

- UL-E322751.pdf

- 2016-12-17

- 72KB

- 850

-

- Download

- Copy Link

- UL-E304945.pdf

- 2016-12-17

- 199KB

- 844

-

- Download

- Copy Link

- TUV(Rast IDC2.5&5.0 pitch).pdf

- 2016-12-17

- 879KB

- 850

-

- Download

- Copy Link

- TUV(IDC 3.96).pdf

- 2016-12-17

- 661KB

- 751

-

- Download

- Copy Link

- TUV(10.0&6.35pitch).pdf

- 2016-12-17

- 721KB

- 768

-

- Download

- Copy Link

- ISO-TS16949(HRB).pdf

- 2016-12-17

- 182KB

- 814

-

- Download

- Copy Link

- cUL-E322751.pdf

- 2016-12-17

- 75KB

- 729

-

- Download

- Copy Link

- cUL-E304945.pdf

- 2016-12-17

- 196KB

- 705

-

- Download

- Copy Link

Company Advantage(Why choose us)

Reliable, certified PCB connectors engineered for stable performance across industries.

Established Experience

Over 16 years manufacturing connectors, offering mature production, proven quality and stable supply.

Certified Quality & Safety

Products comply with ISO 9001, UL/cUL, TS16949, TUV/VDE and IEC 60335-1 Glow-Wire standards, ensuring high reliability and safety.

Rapid Delivery & Flexible Supply

FAQs

Contact Us

Related Blogs

-

Due to the needs of the company's development strategy, the company's name will be officially changed from "Shenzhen Hongru Connector Co., Ltd." to "Shenzhen Haiyuncheng Electronic Co., Ltd." from December 18, 2023. At that time, all businesses under the original company's name will be inherited andproduct News

Due to the needs of the company's development strategy, the company's name will be officially changed from "Shenzhen Hongru Connector Co., Ltd." to "Shenzhen Haiyuncheng Electronic Co., Ltd." from December 18, 2023. At that time, all businesses under the original company's name will be inherited andproduct News

Keep in Touch With Us

Have questions about our PCB connectors or need technical support for your project? HRBCN is here to help. Our team provides fast responses, expert guidance, and reliable solutions tailored to your connector requirements. Reach out today to discuss custom specifications, pricing, or partnership opportunities—we’re ready to support your next design.

Mob: 086-075527096669/086-17612859269

E-mail: sales04@hrb-connector.com

English

English