- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- Home

- Products

- Printed Circuit Board Connector

- Wire to Wire Connector

- Wire to Board Connector

- Board to Board Connector

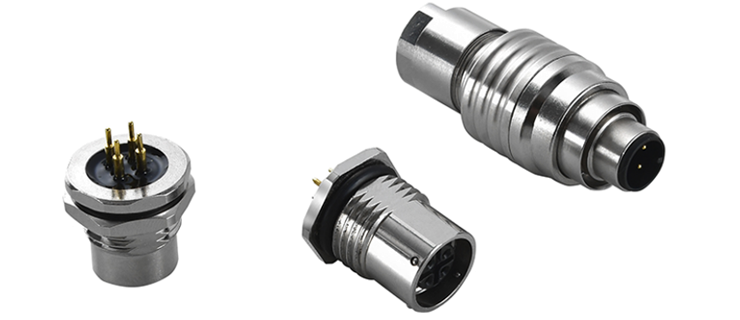

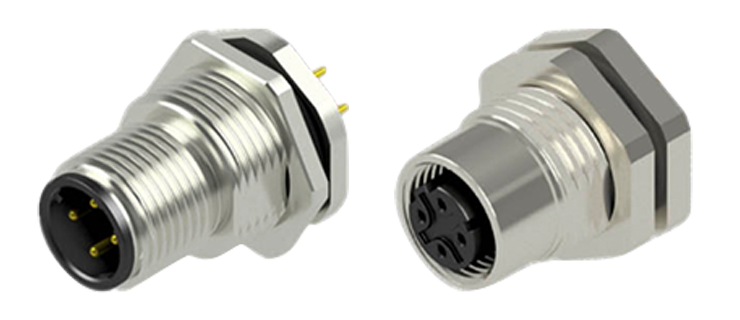

- Circular Connector

- Waterproof connector (IP67)

- Rast Connector

- IDC Connector

- Fully Insulated Quick Disconnect Terminals

- Automobile/Industrial connector

- LED lighting connector

- Tools and harnessing machines

- RF Connector

- Hot

- About Us

- Service

- Certificates

- Application

- News

- Contact Us

English

English