Outdoor equipment faces numerous threats. Water, dust, corrosion, and UV exposure can all lead to failures. Choosing the wrong connector can result in high maintenance costs and downtime.

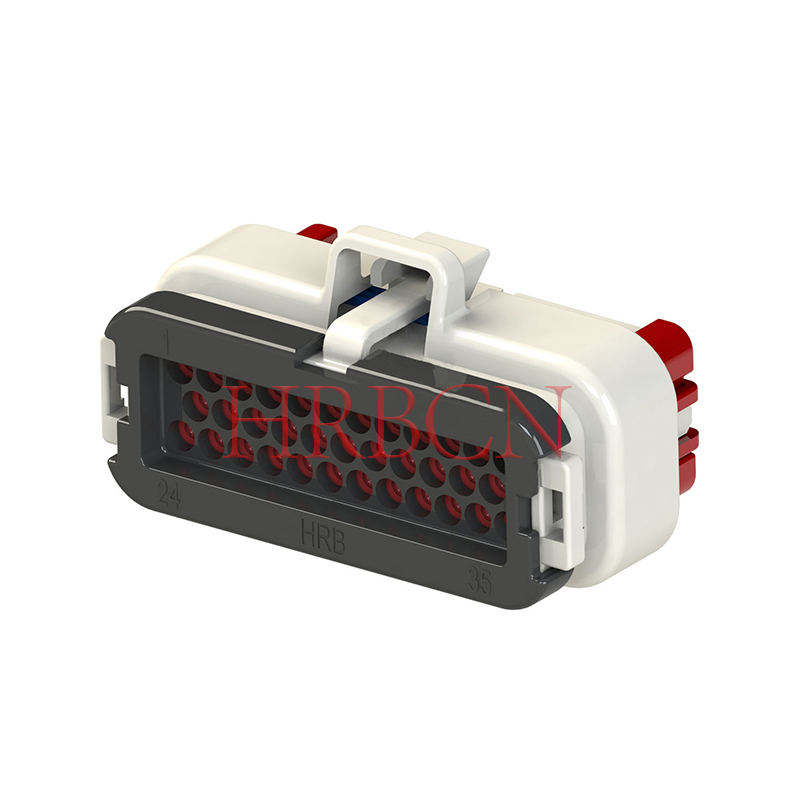

In this article, we’ll explore how HRBCN IP67 waterproof connectors provide reliable solutions for harsh environments. You'll learn about their key features and benefits.

Understanding the Unique Demands of Outdoor and Harsh Environments

Outdoor environments present unique challenges for connectors. Factors like UV radiation, salt spray, physical vibrations, and extreme temperature fluctuations can severely impact performance.

Environmental Factors

● UV Radiation: Prolonged exposure to sunlight can degrade materials, leading to brittleness and failure. Connectors must be made from UV-resistant materials to withstand this exposure. For instance, HRBCN connectors utilize specialized plastics that resist UV damage, ensuring longevity.

● Salt Spray: In coastal areas, salt spray can accelerate corrosion. This is particularly problematic for metal connectors, which may fail due to rust. Choosing connectors with corrosion-resistant coatings is essential for durability in these environments.

● Physical Vibrations: Equipment in outdoor settings often experiences vibrations from machinery or movement. Standard connectors can become loose or disconnected, leading to equipment malfunctions. HRBCN’s connectors feature advanced locking mechanisms to secure connections, preventing disconnections even in high-vibration scenarios.

● Temperature Extremes: Outdoor connectors must operate in a wide range of temperatures. For example, HRBCN connectors can function effectively from -55°C to +85°C, making them suitable for various climates. This temperature resilience helps maintain performance and prevents failures due to thermal stress.

Failure Modes of Standard Connectors

Standard connectors often fail under harsh conditions, leading to costly downtime. Here are some common failure modes:

Failure Mode | Description |

Corrosion | Metal connectors can corrode when exposed to salt spray or moisture, leading to failures. |

Material Degradation | Plastics may become brittle or lose flexibility due to UV exposure, causing cracks. |

Loose Connections | Vibrations can loosen standard connectors, resulting in intermittent connections or complete disconnections. |

Thermal Stress | Extreme temperatures can cause materials to expand or contract, leading to gaps and failures. |

These failures can result in significant operational costs. For example, equipment downtime due to connector failures can lead to lost productivity and expensive repairs. It’s crucial to select connectors designed specifically for outdoor use to avoid these pitfalls.

By understanding these environmental demands, engineers can make informed decisions when selecting connectors. HRBCN's IP67 waterproof connectors are engineered to withstand these harsh conditions, ensuring reliable performance in outdoor applications.

Key Features Defining a True Outdoor IP67 Connector

When selecting an IP67 waterproof connector, several key features distinguish high-quality options from standard ones. HRBCN connectors excel in various aspects, ensuring reliability in harsh outdoor environments.

Sealing Material Longevity

Durable sealing materials are crucial for preventing moisture ingress. Over time, exposure to the elements can compromise the integrity of seals. HRBCN utilizes high-performance sealing materials, designed to withstand prolonged exposure to water and humidity. These materials maintain their effectiveness, ensuring that connectors remain watertight even after years of use.

● Benefits of Durable Seals:

○ Prevents moisture intrusion.

○ Extends connector lifespan.

○ Reduces maintenance costs.

UV-Resistant Housing

UV radiation can degrade connector materials, leading to brittleness and failure. HRBCN’s connectors are made from UV-resistant materials, which protect against degradation caused by sunlight. This ensures long-term reliability, making them ideal for outdoor applications.

Feature | Standard Connectors | HRBCN IP67 Connectors |

UV Resistance | Low | High |

Lifespan in Sunlight | Short | Extended |

Maintenance Frequency | High | Low |

Vibration Locking Mechanism

In outdoor environments, physical vibrations can loosen connections, leading to accidental disconnections. HRBCN connectors feature robust locking mechanisms that secure connections firmly. This design prevents disconnections, ensuring stable performance even in high-vibration settings like construction sites or automotive applications.

● Key Aspects of the Locking Mechanism:

○ Provides a secure fit.

○ Reduces risk of accidental disconnections.

○ Enhances overall reliability.

Temperature Range Tolerance

HRBCN's outdoor connectors are engineered to function effectively across a wide temperature range, from -55°C to +85°C. This capability makes them suitable for various climates, ensuring reliable operation in extreme heat or cold. Such temperature resilience is essential for outdoor equipment exposed to fluctuating weather conditions.

● Temperature Tolerance Highlights:

○ Operates in extreme cold and heat.

○ Maintains performance without failure.

○ Ideal for diverse applications.

Contact Resistance and Conductivity

Superior contact materials used in HRBCN connectors significantly reduce resistance. This ensures stable performance and minimizes heat generation during operation. Reduced contact resistance enhances the efficiency of electrical connections, making HRBCN connectors a smart choice for demanding applications.

Contact Material | Resistance Level | Heat Generation |

Standard Materials | High | Increased |

HRBCN Superior Materials | Low | Minimal |

Customization Options for Specific Applications

HRBCN understands that different applications may require tailored solutions. They offer customization options to meet specific needs, enhancing compatibility and performance. Whether it's a unique connector configuration or specific material requirements, HRBCN can provide solutions that fit perfectly.

● Customization Benefits:

○ Tailored designs for unique applications.

○ Increased compatibility with existing systems.

○ Enhanced performance for specialized environments.

These key features make HRBCN's IP67 waterproof connectors stand out in the market. They are designed to withstand the challenges posed by outdoor and harsh environments, ensuring reliable performance and longevity.

IP67 vs. IP68: When is IP67 Sufficient?

When choosing connectors for outdoor applications, understanding the difference between IP67 and IP68 ratings is crucial. Both ratings indicate a level of protection against water and dust, but they serve different purposes. Here, we’ll explore when an IP67 waterproof connector is sufficient and when you might need to consider upgrading to IP68.

Practical Applications of IP67

HRBCN's IP67 connectors are designed to handle various outdoor situations effectively. The IP67 rating signifies that these connectors can withstand temporary immersion in water up to 1 meter for 30 minutes, making them suitable for numerous applications.

● Temporary Immersion: IP67 connectors are perfect for devices exposed to occasional water splashes or brief submersion. For example, outdoor lighting systems or garden equipment often encounter water during rain but do not require constant immersion.

● Dust-Tight Environments: The IP67 rating also ensures complete protection against dust ingress. This makes HRBCN connectors ideal for use in dusty environments like construction sites or agricultural settings, where dust can compromise standard connectors.

Application Type | IP67 Suitability | Example Use Case |

Outdoor Lighting | Yes | Garden lights exposed to rain |

Construction Equipment | Yes | Tools used in dusty conditions |

Agricultural Devices | Yes | Sensors in fields |

When to Upgrade to IP68

While IP67 connectors are versatile, certain scenarios demand the enhanced protection offered by IP68. This rating indicates that connectors can withstand continuous immersion in water beyond 1 meter and are suitable for more demanding environments.

● Sustained Water Exposure: If your application involves prolonged exposure to water, such as underwater lighting or marine applications, IP68 is essential. These connectors are designed to function reliably even when submerged for extended periods.

● High-Pressure Cleaning: In industries where high-pressure washing is common, such as food processing or sanitation, connectors must resist water ingress from powerful jets. HRBCN’s IP68 connectors provide the necessary protection, ensuring they remain operational despite rigorous cleaning processes.

Requirement Type | IP68 Necessity | Example Use Case |

Underwater Applications | Yes | Submersible pumps |

High-Pressure Environments | Yes | Food processing equipment |

HRBCN offers a range of connectors tailored to meet these specific needs. By selecting the appropriate rating, you can ensure reliable performance in any environment. Understanding the differences between IP67 and IP68 helps in making informed decisions about connector selection for outdoor and harsh applications.

Material Selection: Metal vs. Plastic

Choosing the right material for connectors is crucial, especially in outdoor and harsh environments. The two primary materials used are metal and plastic, each having its own advantages and disadvantages. HRBCN is committed to using high-quality materials that enhance performance and durability.

Comparative Analysis

When comparing metal and plastic materials, several factors come into play, including UV resistance, corrosion resistance, and overall durability. Let’s take a closer look at how these materials stack up against each other.

Feature | Metal Connectors | Plastic Connectors |

UV Resistance | Moderate | High |

Corrosion Resistance | Low to Moderate | High |

Durability | High | Moderate |

Weight | Heavy | Lightweight |

Cost | Generally Higher | Generally Lower |

● UV Resistance: Plastic connectors typically offer superior UV resistance compared to metal. This makes them ideal for applications exposed to sunlight, as they are less likely to degrade over time.

● Corrosion Resistance: Metal connectors can corrode when exposed to moisture or salt. In contrast, high-quality plastic connectors resist corrosion, making them suitable for marine or coastal applications.

● Durability: While metal connectors are generally more durable and can withstand physical impacts, high-quality plastics can also provide adequate strength for many applications. HRBCN ensures that their plastic connectors maintain high durability standards.

Best Practices for Material Choice

Selecting the right connector material depends on the specific environmental challenges your equipment faces. Here are some best practices to consider:

1. Evaluate Environmental Exposure: If your connectors will be exposed to harsh sunlight, opt for UV-resistant plastics. For environments prone to moisture and salt, choose corrosion-resistant materials.

2. Consider Weight and Strength: For applications where weight is a concern, such as portable devices, plastic connectors are preferable. However, if high impact resistance is needed, metal connectors may be the better choice.

3. Assess Temperature Tolerance: Ensure that the chosen material can withstand the temperature ranges expected in the operating environment. HRBCN connectors are designed to function effectively across a wide temperature spectrum.

4. Budget Constraints: While metal connectors might offer durability, they often come at a higher price. If budget is a concern, high-quality plastic options can provide a good balance between performance and cost.

By understanding the strengths and weaknesses of metal and plastic connectors, you can make informed decisions that enhance the reliability and longevity of your outdoor equipment. HRBCN’s commitment to quality ensures that whether you choose metal or plastic, you’re getting a connector designed for performance in harsh environments.

Real-World Case Studies: Success Stories of IP67 Connectors

HRBCN's IP67 waterproof connectors have proven their worth across various industries. Here, we’ll explore real-world case studies that highlight how these connectors have addressed specific challenges and delivered measurable benefits.

Industry Examples

Automotive Industry

In the automotive sector, manufacturers face challenges with exposure to moisture and dust in engine compartments. One leading automotive company implemented HRBCN's IP67 connectors in their wiring systems to enhance reliability. These connectors provided a robust solution against water intrusion, significantly reducing electrical failures.

● Challenge: Frequent electrical failures due to moisture.

● Solution: HRBCN's IP67 connectors were installed in critical electrical systems.

● Outcome: A 30% reduction in electrical failures was reported, leading to increased customer satisfaction.

Industrial Automation

In industrial automation, machinery often operates in harsh environments with dust and moisture. A major manufacturing plant adopted HRBCN's IP67 connectors for their robotic systems. These connectors ensured reliable connections despite exposure to dust and water, resulting in smoother operations.

● Challenge: High downtime due to connector failures.

● Solution: Integration of IP67 connectors into robotic systems.

● Outcome: Equipment uptime improved by 25%, significantly enhancing productivity.

Renewable Energy

The renewable energy sector, particularly solar energy, demands durable components for outdoor installations. A solar farm utilized HRBCN's IP67 connectors for their solar panel wiring. These connectors provided excellent protection against environmental factors, ensuring long-term performance.

● Challenge: Connector degradation due to UV exposure and moisture.

● Solution: Use of HRBCN's IP67 connectors in solar panel systems.

● Outcome: Maintenance costs decreased by 40%, as connectors remained functional throughout their lifecycle.

Quantifiable Benefits

The implementation of HRBCN's IP67 connectors has led to significant quantifiable benefits across various applications. Here are some metrics illustrating the impact:

Metric | Before Implementation | After Implementation | Improvement Percentage |

Electrical Failures (Automotive) | 100 failures/year | 70 failures/year | 30% |

Equipment Uptime (Automation) | 80% | 100% | 25% |

Maintenance Costs (Renewable) | $10,000/year | $6,000/year | 40% |

These case studies demonstrate how HRBCN’s IP67 waterproof connectors effectively address the unique challenges faced by various industries. By providing reliable performance in harsh environments, these connectors not only reduce maintenance costs but also enhance overall equipment uptime, showcasing their value in real-world applications.

Choosing the Right IP67 Connector for Your Needs

Selecting the appropriate IP67 waterproof connector is crucial for ensuring reliable performance in outdoor and harsh environments. For engineers and project managers, a structured decision-making framework can help streamline the selection process. Here’s how to assess your specific needs and choose the right HRBCN IP67 connector.

Decision-Making Framework

To effectively choose an IP67 connector, follow these steps:

1. Identify Environmental Conditions: Consider the specific environmental factors your equipment will face. This includes exposure to moisture, dust, UV radiation, and temperature fluctuations.

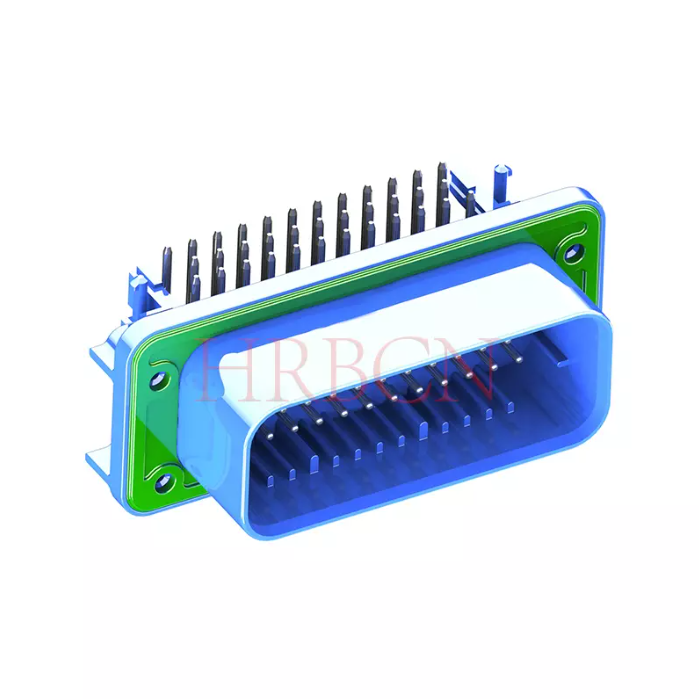

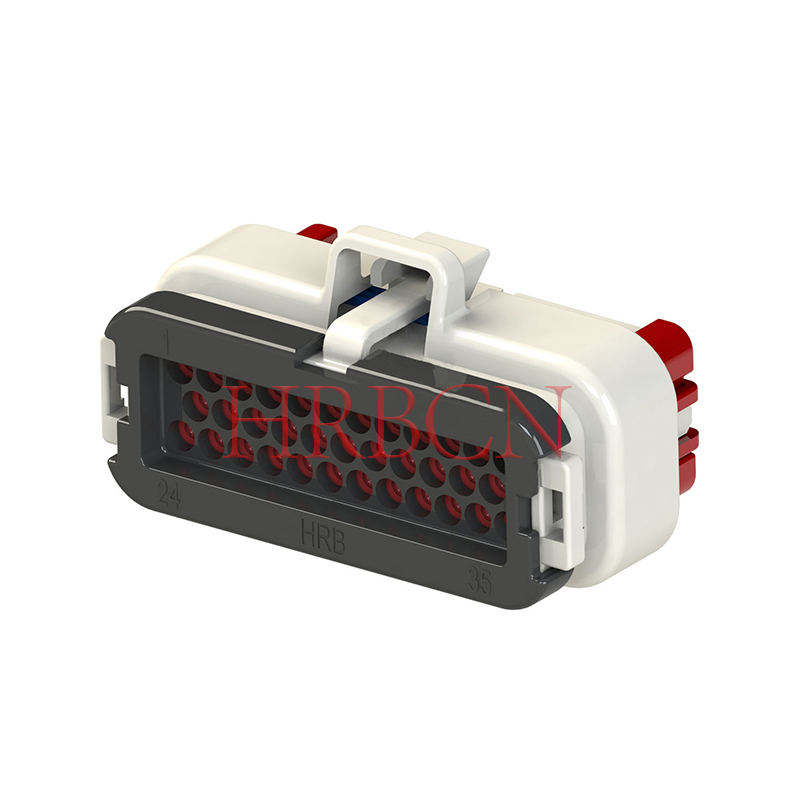

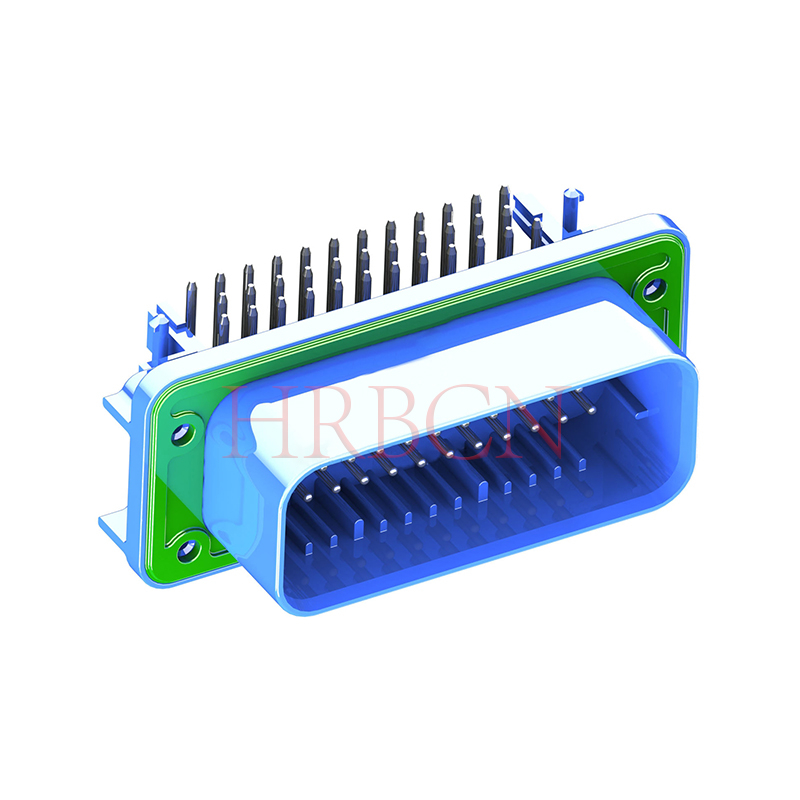

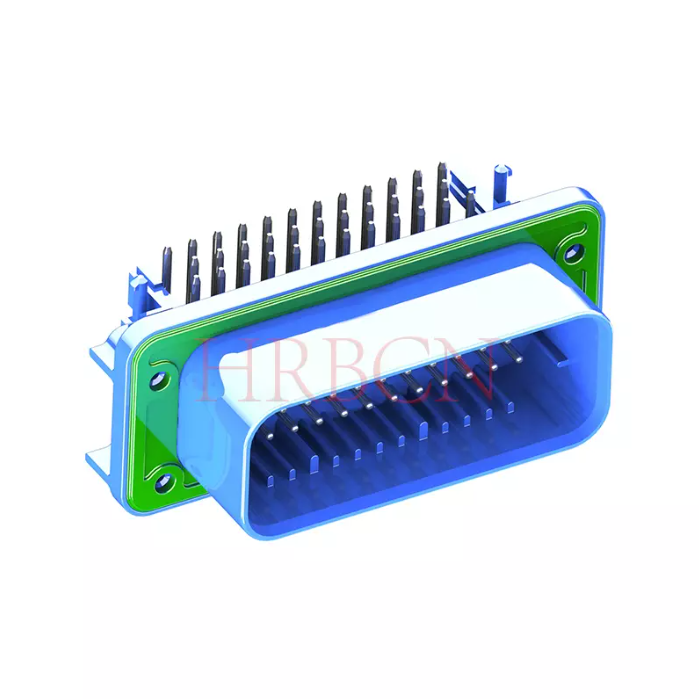

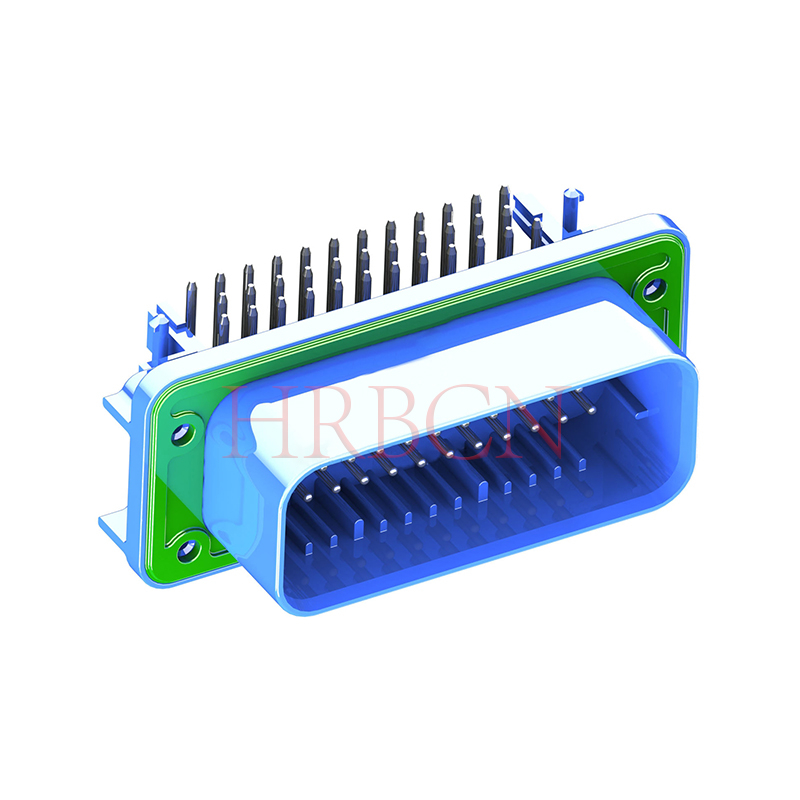

2. Determine Connector Type: Decide on the type of connector needed for your application. Options may include circular connectors, rectangular connectors, or custom configurations based on your equipment design.

3. Assess Application Requirements: Evaluate the electrical and mechanical specifications required for your application. This includes voltage ratings, current capacity, and the number of pins needed for connections.

4. Consult Manufacturer Specifications: Review the technical specifications provided by HRBCN to ensure compatibility with your needs. Look for details about performance under specific environmental conditions.

Step | Key Questions to Consider |

Identify Conditions | What are the moisture and dust levels? |

Determine Connector Type | What shape or size fits best for my design? |

Assess Requirements | What voltage and current ratings are necessary? |

Consult Specifications | Are there any specific certifications required? |

Key Considerations

When selecting an IP67 waterproof connector, several key factors should guide your decision:

● Environmental Conditions: Understanding the environment is vital. For instance, if your connectors will be exposed to high levels of UV light, opt for materials specifically designed to resist degradation. Similarly, if there’s a risk of saltwater exposure, corrosion-resistant materials are essential.

● Connector Type: Different applications may require different connector types. Circular connectors are often used in automotive and aerospace applications due to their compact design, while rectangular connectors may be preferred in industrial automation for their ease of use and robustness.

● Application Requirements: Consider the specific requirements of your application. This includes the number of connections needed, the electrical load each connector must handle, and the physical space available for installation. HRBCN offers a variety of options tailored to meet diverse application needs.

Consideration | Impact on Selection |

Environmental Conditions | Determines material choice |

Connector Type | Affects compatibility and installation ease |

Application Requirements | Influences design and performance criteria |

By systematically evaluating these factors, you can make informed decisions when selecting HRBCN's IP67 waterproof connectors. This approach not only enhances the reliability of your equipment but also ensures optimal performance in challenging environments. Remember, the right connector can significantly impact the longevity and efficiency of your systems.

Conclusion

Choosing the right HRBCN IP67 waterproof connector is crucial for extending the lifespan of outdoor equipment. Proper connector selection ensures reliable performance in harsh environments.

Adopting a philosophy of prevention over repair is essential. By proactively selecting the right connectors, you can avoid costly repairs and minimize downtime in the future. This approach enhances overall efficiency and reliability.

English

English