describe:

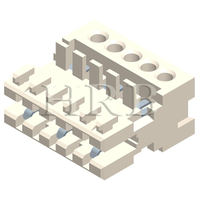

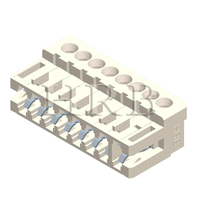

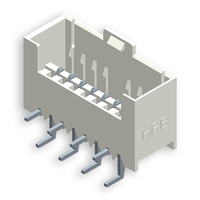

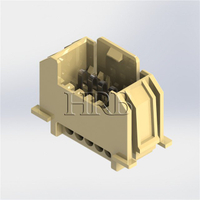

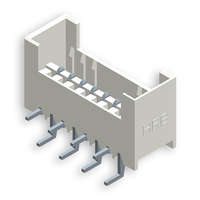

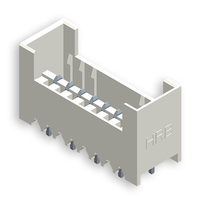

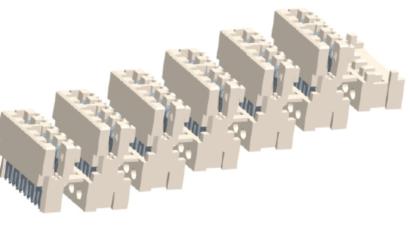

RAST 2.5 connectors for direct mating, Insulation Displacement Technology (IDT), PCB locking via locking hook, or with or without keying ribs and closed sides, for single conductors

Contact distance 2.5mm

Mounts directly on PCB, externally coded, internally coded wall and side locked to PCB, side walls optional.The number of pins ranges from 3 to 19.

Technical Parameters:

1).Rated current: 3A AC, DC

2).Rated voltage: 32V AC, DC

3).Operating temperature: -40˚C - +120˚C

4).Contact resistance: maximum 10mΩ

5).Insulation resistance: minimum 1000MΩ.

6).Withstand voltage: 1400V AC/minute

7).Material: Shell: Nylon 66 UL94V-0

Terminals: Phosphor bronze, tin plated

9).Wire range: AWG 24 to 22

GWT: 750˚CIEC-60335-1

Material number information:

M7289-X-X X-X-X(X)

①②③④⑤⑥⑦

①: HRB product series number

②: PIN number (3 to 19)

③: Left wall:

Answer: There are no side walls.

B: 0.6mm side wall.

④:Yes Side wall:

Answer: There are no side walls.

B: 0.6mm side wall.

⑤: Number of solid ribs:

0: No solid ribs.

1: There is a solid rib between pos.1 and pos.2.

2: There is a solid rib between pos.2 and pos.3.

etc.

⑥:Plating quantity:

Blank: tin plated.

00H: Selective gold plating 1U''

02H: Selective gold plating 2U''

03H: Selective gold plating 3U''

⑦: Wire range:

2:AWG22

4:AWG24

Packaging Information:

| size |

SPQ |

MOQ |

| Pos.No. | A | B |

| 2 | 2.5 | 7.5 | 16500pcs | 33000pcs |

| 3 | 5.0 | 10.0 | 12500pcs | 37500pcs |

| 4 | 7.5 | 12.5 | 10000pcs | 30000pcs |

| 5 | 10.5 | 15.0 | 8000pcs | 32000pcs |

| 6 | 12.5 | 17.5 | 7000pcs | 35000pcs |

| 7 | 15.0 | 20.0 | 6000pcs | 30000pcs |

| 8 | 17.5 | 22.5 | 5500pcs | 33000pcs |

| 9 | 20.0 | 25.0 | 5000pcs | 30000pcs |

| 10 | 22.5 | 27.5 | 4500pcs | 31500pcs |

| 11 | 25.0 | 30.0 | 4000pcs | 32000pcs |

| 12 | 27.5 | 32.5 | 3500pcs | 31500pcs |

| 13 | 30.0 | 35.0 | 3500pcs | 31500pcs |

| 14 | 32.5 | 37.5 | 3000pcs | 30000pcs |

| 15 | 35.0 | 40.0 | 3000pcs | 30000pcs |

| 16 | 37.5 | 42.5 | 2500pcs | 30000pcs |

| 17 | 40.0 | 45.0 | 2500pcs | 30000pcs |

| 18 | 42.5 | 47.5 | 2500pcs | 30000pcs |

| 19 | 45.0 | 50.0 | 2500pcs | 30000pcs |

| 20 | 47.5 | 52.5 | 2000pcs | 30000pcs

|

IDC advantages:

1).While crimping the IDC, immediately punch holes to remove the oxide on the surface of the wires and terminals to make good contact between the conductors.

2).Simplify wiring harness design

Reduce incorrect assembly

We can choose single color in IDC's mass production to reduce inventory and purchase various colors for wires to facilitate material management.Process or crimp the first time and crimp the complete harness the second time.Each line is given corresponding to the electrical signal error caused by avoiding confusing holes.

3).Up to now, using IDC, pre-assembled factory-direct finished wire harness components have been optimized, as well as various foolproof hook designs to minimize the reliance on skilled workers to assemble finished products, which can be assembled according to the product structure and reduce costs.

4).We have taken into account the subsequent widespread use around the world, that is, all metal parts are embedded in plastic casings to avoid extrusion during local and international transportation, causing damage and destruction of IDC connectors, and reduce transportation losses.

IDC Rast product applications:

| 1. Computer industry: | Desktops, laptops, tablets, servers, etc. |

| 2.Office Supplies: | Copiers, printers, scanners, fax machines, etc. |

| 3.Communication: | Video phone, public phone, fiber optic crimping, etc. |

| 4. Financial business: | ATM machine, POS machine, five signature recorder, etc. |

| 5. Home appliances: | Washing machines, dishwashers, vacuum cleaners, treadmills, smart meters, coffee machines. |

| 6. Automobile industry: | Power steering, electric seats, sound, lights, EPS, OPS, etc. |

M7289.pdf

M7289.pdf

English

English