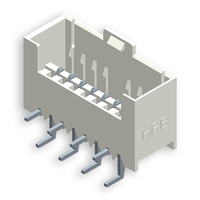

In smart manufacturing, reliability is crucial. As factories become more automated, robust connectivity solutions are essential.

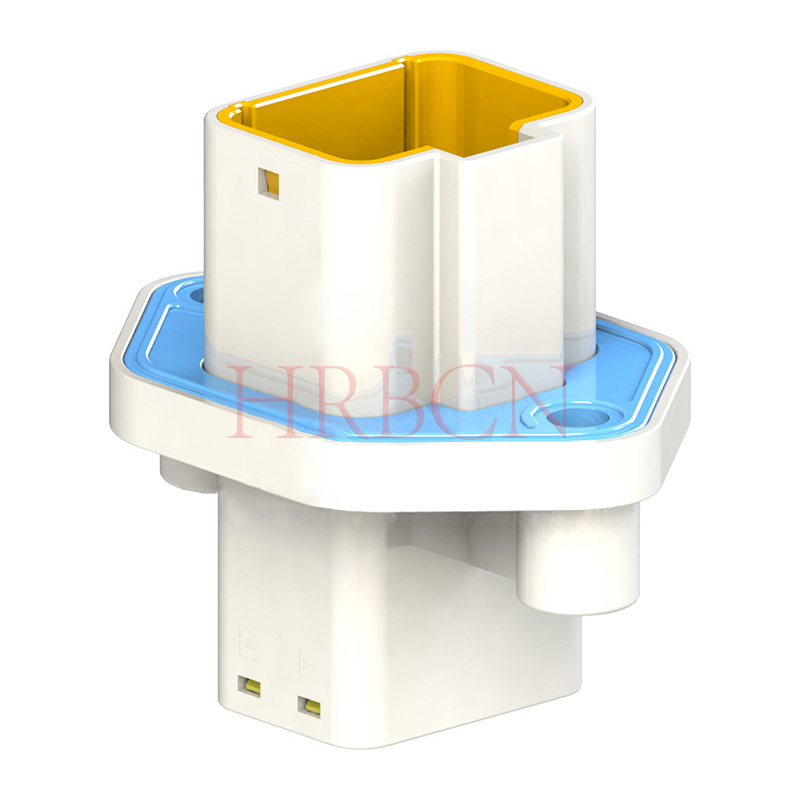

IP67 waterproof connectors, like those from HRBCN, ensure electrical connections remain intact in harsh environments.

In this article, we’ll explore the applications of IP67 connectors and how they solve issues like downtime and liquid ingress.

Introduction

In the realm of smart manufacturing, the demand for equipment reliability has reached unprecedented levels. As factories evolve into automated ecosystems, the need for robust connectivity solutions becomes critical. IP67 waterproof connectors, such as those offered by HRBCN, play a pivotal role in ensuring that electrical connections remain intact and operational, even in the most challenging environments.

The Importance of Reliable Connectivity

In modern manufacturing settings, unexpected downtime can lead to significant losses. Equipment failures often stem from poor connections, especially in environments exposed to moisture, dust, and temperature fluctuations. IP67 connectors are designed to combat these issues, providing a reliable solution that minimizes the risk of signal interference and liquid ingress.

Challenge | Impact on Manufacturing | Solution Offered by IP67 Connectors |

Unexpected Downtime | Loss of productivity | Enhanced reliability |

Signal Interference | Compromised data integrity | Robust sealing technology |

Liquid Ingress | Equipment damage | Waterproof and dust-tight design |

High Maintenance Costs | Increased operational expenses | Durable materials and construction |

Applications in Smart Manufacturing

This article delves into specific applications of IP67 connectors within smart manufacturing, highlighting their effectiveness in addressing common pain points. From environmental sensors in IIoT networks to connectors in food processing lines, these robust solutions are indispensable for maintaining operational efficiency.

Key Areas of Focus:

● Environmental Sensors: Ensuring reliable data transmission in harsh conditions.

● Robotic Systems: Providing stable connections for automated guided vehicles (AGVs).

● Food Processing: Meeting stringent hygiene standards while preventing liquid ingress.

By integrating HRBCN's IP67 waterproof connectors, manufacturers can enhance the reliability of their systems, reduce maintenance costs, and improve overall efficiency. This focus on robust connectivity is essential for thriving in today’s competitive landscape.

Core Applications

Industrial Automation and Robotics

1.1 Ensuring Signal Integrity in Robotic Arms

Industrial robotic arms work in dynamic settings where movement and vibration are constant. These conditions can lead to signal loss, which disrupts operations. By integrating HRBCN's IP67 waterproof connectors, manufacturers can ensure stable power and signal transmission.

These connectors are designed to withstand dust and moisture, significantly reducing the risk of failure. For example, a study showed that using IP67 connectors decreased downtime by 30% in robotic applications. This reliability is crucial for maintaining productivity in automated environments.

Feature | IP67 Waterproof Connector | Standard Connector |

Dust Protection | Yes | No |

Water Immersion Resistance | Yes | No |

Vibration Resistance | High | Low |

1.2 Enhancing Performance in CNC Machining

CNC machines are vital in manufacturing but often face coolant splashes and metal shavings. These elements can compromise sensitive electronic connections. Utilizing HRBCN's IP67 connectors helps protect these connections from damage, ensuring uninterrupted operation during machining processes.

The robust design of these connectors prevents short circuits, allowing CNC machines to operate smoothly. This is particularly important in high-precision environments where even minor disruptions can lead to significant losses. Additionally, the connectors' resistance to various contaminants enhances their longevity, making them a smart investment.

● Key Benefits of IP67 Connectors in CNC Machining:

○ Prevents coolant ingress

○ Reduces maintenance frequency

○ Enhances operational efficiency

1.3 Optimizing Conveyor Systems

Conveyor systems are the backbone of assembly lines, but they often face contamination from dust and oils. This can lead to equipment failures and increased maintenance costs. HRBCN's IP67 connectors provide a dust-tight seal, safeguarding electronic components from harmful contaminants.

By using these connectors, manufacturers can minimize maintenance needs and ensure smooth operation. The IP67 rating guarantees that these connectors remain functional even in harsh environments, which is essential for maintaining productivity.

Advantages of Using IP67 Connectors in Conveyor Systems:

Benefit | Description |

Dust-tight Seal | Protects against dust contamination |

Reduced Downtime | Fewer interruptions in production |

Cost-effective Maintenance | Lower maintenance requirements over time |

Incorporating HRBCN's IP67 waterproof connectors into industrial automation and robotics not only enhances the reliability of robotic arms, CNC machines, and conveyor systems but also contributes to a more efficient manufacturing process overall. This integration is key to achieving the goals of smart manufacturing.

Sensors and Actuators in IIoT Networks

2.1 Robust Connectivity for Environmental Sensors

In smart factories, environmental sensors play a vital role in monitoring conditions such as temperature, humidity, and pressure. However, these sensors often operate in challenging environments filled with dust and moisture. To ensure reliable data transmission, HRBCN's IP67 waterproof connectors are essential.

These connectors provide a robust solution, allowing sensors to function optimally even under harsh conditions. The IP67 rating guarantees protection against dust ingress and temporary immersion in water, which is crucial for maintaining operational efficiency. For instance, factories using these connectors have reported a significant reduction in sensor failures.

Feature | IP67 Waterproof Connector | Standard Connector |

Dust Protection | Yes | No |

Water Immersion Resistance | Yes | No |

Reliability in Harsh Conditions | High | Low |

Advantages of Using IP67 Connectors for Sensors:

● Improved Data Integrity: Stable connections prevent data loss.

● Extended Lifespan: Protects sensors from environmental damage.

● Reduced Downtime: Fewer maintenance issues lead to continuous operation.

2.2 Reliability in Actuator Control

Actuators are critical components in any automated system, controlling processes from robotic movements to conveyor operations. They require stable electrical connections to function properly. HRBCN's IP67 connectors are designed to prevent liquid ingress, making them ideal for environments where wash-down processes are common.

For example, in food processing plants, actuators may be exposed to cleaning agents and high-pressure water. Using IP67 connectors ensures that these components remain operational without the risk of short circuits. This reliability is essential for maintaining production efficiency and safety.

Key Benefits of IP67 Connectors for Actuators:

Benefit | Description |

Liquid Ingress Prevention | Keeps electrical connections safe from moisture |

Enhanced Performance | Ensures actuators operate correctly in all conditions |

Lower Maintenance Costs | Reduces frequency of repairs and replacements |

Incorporating HRBCN's IP67 waterproof connectors into IIoT networks enhances the functionality of sensors and actuators. This integration ensures that smart manufacturing systems operate smoothly, even in the most demanding environments, making them indispensable for modern industrial applications.

Outdoor and Harsh Environment Applications

3.1 Resilience in Outdoor Smart Infrastructure

In the realm of smart cities, outdoor applications demand reliable connectivity. HRBCN's IP67 waterproof connectors are designed to withstand harsh environmental conditions, including rain, salt spray, and extreme temperatures. These connectors ensure that network stability is maintained, preventing signal loss and ensuring uninterrupted service.

For example, smart traffic lights and environmental monitoring stations rely on these connectors to function effectively in all weather conditions. The ability to resist corrosion from salt and moisture is crucial for longevity and performance.

Feature | IP67 Waterproof Connector | Standard Connector |

Rain Resistance | Yes | No |

Salt Spray Resistance | Yes | No |

Temperature Tolerance | Wide Range | Limited |

Benefits of Using IP67 Connectors in Outdoor Applications:

● Enhanced Durability: Designed to last in tough environments.

● Consistent Performance: Reliable signal transmission regardless of weather.

● Lower Maintenance: Reduces the need for frequent repairs or replacements.

3.2 Adaptability in Mobile Robotics

Automated Guided Vehicles (AGVs) operate in diverse conditions, from warehouses to outdoor settings. The reliability of their connections is paramount for smooth operation. HRBCN's IP67 connectors are engineered to provide anti-loosening mechanisms and vibration resistance, which are essential during high-speed movements.

These features ensure that connections remain intact, even when AGVs navigate rough terrains or experience sudden stops. The connectors' robust design helps prevent disconnections and failures, contributing to the overall safety and efficiency of mobile robotics.

Key Advantages of IP67 Connectors for AGVs:

Benefit | Description |

Anti-loosening Mechanism | Prevents disconnections during operation |

Vibration Resistance | Maintains connection integrity under movement |

Versatile Application | Suitable for various operational environments |

By integrating HRBCN's IP67 waterproof connectors into outdoor and harsh environment applications, manufacturers can ensure that their systems operate reliably. This adaptability is critical for the success of smart infrastructure and mobile robotics, making these connectors a vital component in modern manufacturing.

Food and Beverage Processing

4.1 Meeting Hygiene Standards in Wash-down Environments

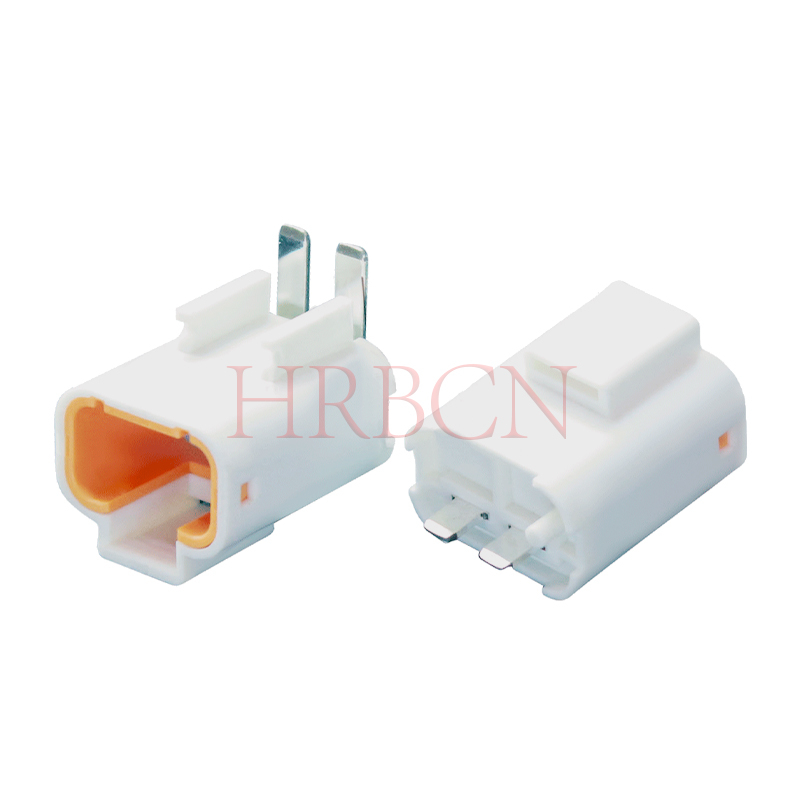

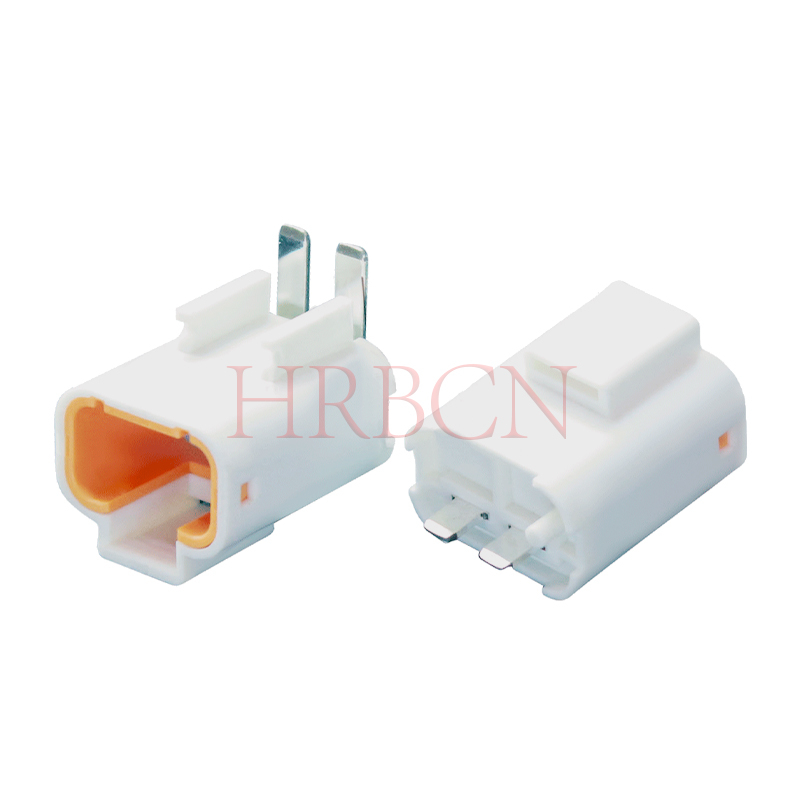

In the food production industry, maintaining hygiene is crucial. Equipment often undergoes rigorous cleaning processes to meet strict health regulations. HRBCN's IP67 waterproof connectors are specifically designed to withstand these wash-down environments, preventing liquid ingress during cleaning.

This protection ensures compliance with hygiene standards while maintaining signal integrity. For example, in meat processing plants, where equipment is frequently cleaned with high-pressure water jets, using IP67 connectors helps avoid contamination and equipment failure.

Feature | IP67 Waterproof Connector | Standard Connector |

Liquid Ingress Protection | Yes | No |

Compliance with Hygiene Standards | Yes | No |

Durable Under High Pressure | Yes | Limited |

Advantages of IP67 Connectors in Hygiene Compliance:

● Prevents Contamination: Keeps electrical components safe from cleaning agents.

● Ensures Reliability: Maintains performance during and after wash-downs.

● Reduces Downtime: Fewer maintenance issues lead to continuous operation.

4.2 Protecting Equipment in Processing Lines

Food processing lines are exposed to moisture and various cleaning agents. Therefore, they require connectors that can withstand these harsh conditions. HRBCN's IP67 connectors provide reliable performance, ensuring that equipment operates smoothly while minimizing the risk of failure.

These connectors are built to endure the challenges of food processing environments, where exposure to water and cleaning chemicals is routine. By using IP67 connectors, manufacturers can reduce equipment downtime and enhance overall productivity.

Key Benefits of IP67 Connectors for Food Processing:

Benefit | Description |

Moisture Resistance | Protects connections from water and cleaning agents |

Enhanced Durability | Designed to last in tough processing environments |

Lower Risk of Failure | Ensures continuous operation without interruptions |

Incorporating HRBCN's IP67 waterproof connectors into food and beverage processing not only meets hygiene standards but also enhances the reliability of equipment. This integration is essential for maintaining efficiency in food production, making these connectors a critical component in the industry.

Technical Advantages and Comparisons

Why IP67 Over IP54 or Standard Connectors?

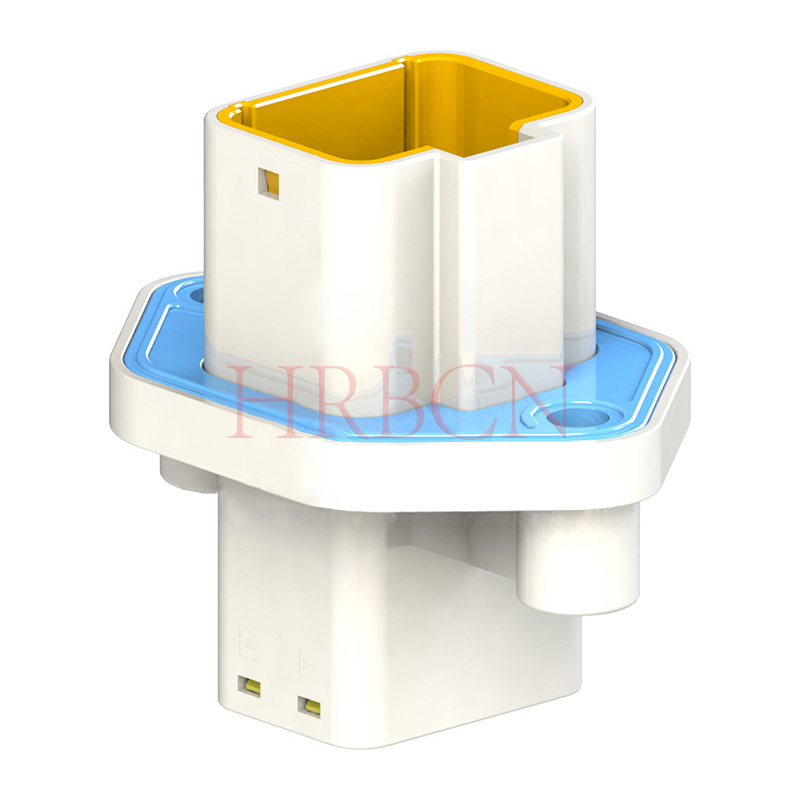

In environments where moisture and dust are prevalent, choosing the right connector is crucial. HRBCN's IP67 connectors provide superior protection compared to IP54-rated connectors. The IP67 rating indicates that these connectors can withstand immersion in water up to 1 meter for 30 minutes, making them essential for applications where reliability is non-negotiable.

To illustrate the differences, let’s compare the technical specifications of IP67 connectors with IP54 connectors. The robust sealing performance of HRBCN's IP67 connectors ensures they can endure harsher conditions, which is vital in smart manufacturing settings.

Specification | IP67 Waterproof Connector | IP54 Connector |

Water Immersion | Up to 1 meter for 30 mins | No immersion allowed |

Dust Protection | Complete dust-tight seal | Limited dust ingress |

Operating Temperature Range | -40°C to +85°C | -20°C to +70°C |

Key Technical Advantages of HRBCN's IP67 Connectors:

● Robust Sealing Performance: The advanced sealing technology prevents water and dust ingress, ensuring long-lasting functionality in challenging environments.

● Durable Materials: Made from high-quality materials, these connectors resist corrosion and wear, which is essential for maintaining performance over time.

● Versatile Applications: Ideal for various industries, including food processing, outdoor infrastructure, and robotics, where reliability is critical.

Performance Under Stress

The ability of IP67 connectors to function under stress is another significant advantage. In manufacturing environments, equipment often experiences vibrations and shocks. HRBCN's connectors are designed to handle these stresses while maintaining a secure connection.

Benefits of Enhanced Performance:

● Vibration Resistance: These connectors remain securely fastened even during high-speed operations, reducing the risk of disconnections.

● Longevity: The durable construction means fewer replacements and lower maintenance costs over time.

By selecting HRBCN's IP67 waterproof connectors, manufacturers can ensure their systems operate reliably, even in the most demanding conditions. This choice not only enhances operational efficiency but also contributes to the overall safety and effectiveness of smart manufacturing processes.

Conclusion

Integrating HRBCN's IP67 waterproof connectors in smart manufacturing is essential for enhancing overall equipment effectiveness (OEE). These connectors address critical challenges posed by harsh environments. They significantly improve the reliability and efficiency of modern industrial systems. As manufacturers aim for higher performance and lower maintenance costs, the importance of these connectors continues to grow. Their role in achieving operational excellence is vital for success in today’s competitive landscape.

English

English